Case Study

Case Study

Case Study

Order Accuracy Optimization Tool

Order Accuracy Optimization Tool

Order Accuracy Optimization Tool

Custom Ink is an online retailer that provides customized apparel and accessories for groups, businesses, and events. With over 4,000 products across more than 100 categories like t-shirts, sweatshirts, activewear, hats, bags, and drinkware, a streamlined workflow was imperative to correctly map supplier product information with the Custom Ink catalog.

Custom Ink is an online retailer that provides customized apparel and accessories for groups, businesses, and events. With over 4,000 products across more than 100 categories like t-shirts, sweatshirts, activewear, hats, bags, and drinkware, a streamlined workflow was imperative to correctly map supplier product information with the Custom Ink catalog.

Mapping Mishaps: Costly Confusion

Challenge

Even with 4,000+ products in Custom Ink's catalog and hundreds of new products being added weekly, "Product missing or not mapped" accounted for 20% of automated business operations (ABO) failures. The previous process to get products added to or updated in Custom Ink's catalog when mismatched or missing was tedious and time consuming, and the lift relied entirely on engineers. Custom Ink would continue to lose out on increased ABO rates, quicker time to service these issues, and poor experiences by not solving for an improvement to the overall process.

Even with 4,000+ products in Custom Ink's catalog and hundreds of new products being added weekly, "Product missing or not mapped" accounted for 20% of automated business operations (ABO) failures. The previous process to get products added to or updated in Custom Ink's catalog when mismatched or missing was tedious and time consuming, and the lift relied entirely on engineers. Custom Ink would continue to lose out on increased ABO rates, quicker time to service these issues, and poor experiences by not solving for an improvement to the overall process.

User Goals

Automatically download new products from all network suppliers on a weekly basis

During product import, the application looks at updates to the supplier catalogs and creates new mapping suggestions, product updates, and product removals

Have an audit log of any changes made within the application

Have ability to override sizes and colors for each supplier

Automatically download new products from all network suppliers on a weekly basis

During product import, the application looks at updates to the supplier catalogs and creates new mapping suggestions, product updates, and product removals

Have an audit log of any changes made within the application

Have ability to override sizes and colors for each supplier

Business Goals

Create an entirely new interface application for the sourcing and logistics team to easily take on the mapping product tasks

Save 4 full time employees (FTE)

Create an entirely new interface application for the sourcing and logistics team to easily take on the mapping product tasks

Save 4 full time employees (FTE)

Mapping Mishaps: Costly Confusion

Meet the Team

Meet the Team

1 Lead Designer

1 Product Manager

1 Project Manager

2 Software Engineers

1 Lead Designer

1 Product Manager

1 Project Manager

2 Software Engineers

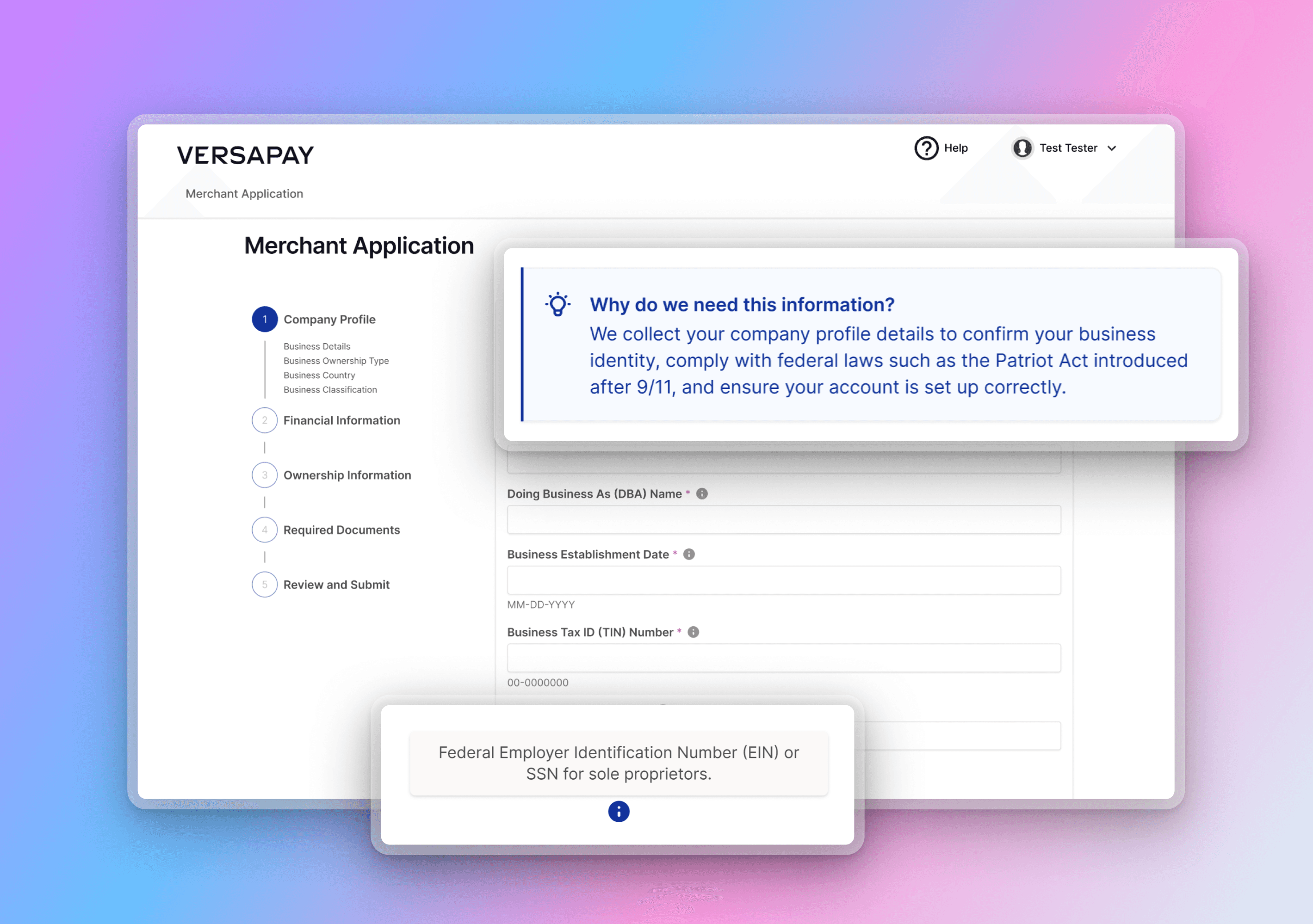

Before 👎

The incredibly manual tool engineers built to fulfill a crucial workflow need. Unfortunately, it was a sea of information with little to organize it all.

The incredibly manual tool engineers built to fulfill a crucial workflow need. Unfortunately, it was a sea of information with little to organize it all.

Before 👎

After 👍

Entirely new tool complete with supplier updates dashboard, mapping results filtered by least accurate to accurate, and admin rights.

After 👍

Entirely new tool complete with supplier updates dashboard, mapping results filtered by least accurate to accurate, and admin rights.

Why is Everything so Manual?

After conducting three user interviews with the main engineers using this workflow, I discovered all the entirely manual processes that were slowing them down.

Downloading supplier catalogs

Checking each individual product for incorrect matchings

All information was shown all at once

Nothing could be filtered down to make information easier to parse through

Cross-Functional Team Synergy

I set up weekly working sessions with the product team and engineers that I was solving for, starting with low fidelity sketches and wireframes to narrow direction. Having visuals as talking points during these meetings were incredibly helpful at getting the entire working team on the same page.

In order to keep the project within scope, I designed with the minimum viable product (MVP) in mind. Through weekly calls with engineers and the collaborative relationship we'd built over time, we discussed questions, potential hurdles, and solutions.

Concepting with engineers and product in weekly working sessions

Concepting with engineers and product in weekly working sessions

First Try

After multiple working sessions, the first draft was born to determine what kind of information architecture and hierarchy would communicate the needs best.

Refining the Final Designs

After going through four weeks of collaborative sessions, design workshops and more user testing, I created these final screens for the Product Mapper.

The tool has since expanded in scope and usability, now enabling sourcing, logistics, and operations teams to autonomously correct and update catalog data with minimal engineering support. This positions the business to reduce dependencies, cut down on human error, and scale product accuracy across fulfillment systems.

Why is Everything so Manual?

After conducting three user interviews with the main engineers using this workflow, I discovered all the entirely manual processes that were slowing them down.

Downloading supplier catalogs

Checking each individual product for incorrect matchings

All information was shown all at once

Nothing could be filtered down to make information easier to parse through

Dashboard - A quick overview of all the suppliers in our network in a dashboard view. New products were automatically downloaded every week.

Mapping Results - Once an individual supplier is selected, team members will see a list view of all the products needing review. Any mismatched data will be highlighted in red text, and the confidence match rating will reflect how accurate the matching is. Any confidence match rating under 70% is usually scrutinized further to ensure information is updated correctly.

Simple approval screen to confirm all possible mappings have been processed.

Admin Panel and Mapping Editor - The Manual Editor page gives team members an easy way to manually override size & color that applies to all future mappings and improves machine learning over time.

Cross-Functional Team Synergy

I set up weekly working sessions with the product team and engineers that I was solving for, starting with low fidelity sketches and wireframes to narrow direction. Having visuals as talking points during these meetings were incredibly helpful at getting the entire working team on the same page.

In order to keep the project within scope, I designed with the minimum viable product (MVP) in mind. Through weekly calls with engineers and the collaborative relationship we'd built over time, we discussed questions, potential hurdles, and solutions.

First Try

After multiple working sessions, the first draft was born to determine what kind of information architecture and hierarchy would communicate the needs best.

Refining the Final Designs

After going through four weeks of collaborative sessions, design workshops and more user testing, I created these final screens for the Product Mapper.

The tool has since expanded in scope and usability, now enabling sourcing, logistics, and operations teams to autonomously correct and update catalog data with minimal engineering support. This positions the business to reduce dependencies, cut down on human error, and scale product accuracy across fulfillment systems.

Dashboard - A quick overview of all the suppliers in our network in a dashboard view. New products were automatically downloaded every week.

Simple approval screen to confirm all possible mappings have been processed.

Admin Panel and Mapping Editor - The Manual Editor page gives team members an easy way to manually override size & color that applies to all future mappings and improves machine learning over time.

Mapping Results - Once an individual supplier is selected, team members will see a list view of all the products needing review. Any mismatched data will be highlighted in red text, and the confidence match rating will reflect how accurate the matching is. Any confidence match rating under 70% is usually scrutinized further to ensure information is updated correctly.

Reflection

Reflection

This was a high-impact initiative driven by engineering, ambitious in scope with just six weeks to deliver. Engineers flagged a major automation opportunity in a highly manual, error-prone workflow that accounted for 20% of order issues. I partnered closely with them and product stakeholders to untangle a deeply technical problem space and rapidly design an intuitive tool that could serve as the foundation for future ML-powered catalog management.

Feedback from engineering leadership reinforced the strategic value of design in this space:

“This is a new UI that never existed before, and devs didn’t have a set vision for the UX, so it was nice to see the new ideas we embraced together.”

“This is a new UI that never existed before, and devs didn’t have a set vision for the UX, so it was nice to see the new ideas we embraced together.”

If extended, I would focus on:

Embedding lightweight AI or rule-based suggestions to catch mismatches early

Continuing weekly working sessions to reduce downstream QA bottlenecks

Building internal training to accelerate adoption across non-technical teams

Testing workflows with sourcing and logistics to validate end-to-end usability

Establishing a feedback loop for continuous iteration and intelligent optimization

© Jimin Ngo 2026